Knife Making: A Challenging Pursuit

- Randy Reek

- Oct 19, 2017

- 4 min read

What does a "Knife Guy" do when he is not sharpening knives or throwing knives? He MAKES knives!

Knife making is another of my hobbies. I call it a hobby because I rarely sell a knife or am asked to create a special knife order. Instead, I make knives to fit my special requirements - or just for fun to create a unique knife for my collection.

One type of knife that I create is for throwing. If you read my previous article on knife throwing, you now understand that there are several styles of throwing, each with its own knife design. In addition, each style of knife throwing is also affected by your personal technique and your physical attributes.

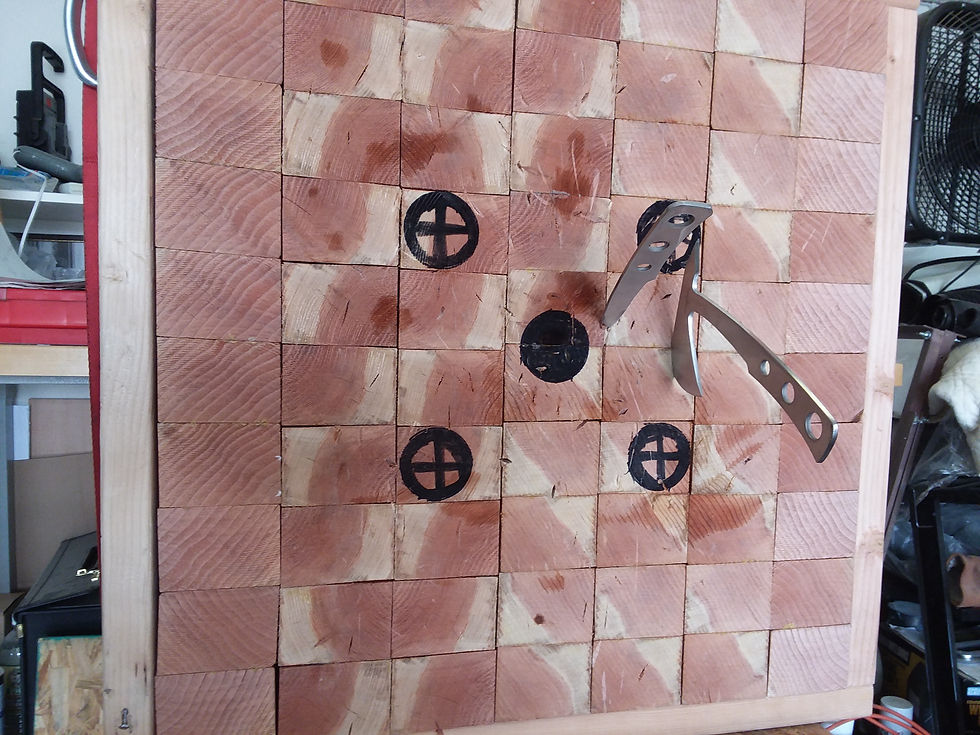

So sometimes I make changes to stock knives. As shown in a video discussing knives for beginner knife throwers (see the previous article) I modified one set of knives to have sharper points. The stock knives were more rounded and just didn't stick in my hard wood target. After reprofiling these knives I had much better success using both the half-spin and full-spin throwing style.

Next, I took the same stock knives and modified them for the no-spin throwing style. No-spin throwing is more effective with a knife that is balanced or has more weight at the handle. By cutting down the stock knives to a thinner profile, and removing the bump on the handle I created a knife that throws better for no-spin. The new thinner profile is shown below the original knife.

Because of the special properties of knives for throwing no-spin, I have made several throwing knives from scratch. Obviously, this is much more time consuming, but allows me to also customize the knives to fit my style.

The knives above are strictly for throwing. They are thick, one-quarter inch steel and would barely cut butter, but they have sharp points! After cutting out the rough shape, the knife is brought to the finished shape on a bench grinder. Such a grinder aggressively removes steel and is NEVER used in knife sharpening.

After grinding to the finished shape, the knife is further refined on a belt sander using a coarse belt. Likewise, this wide and coarse belt can not be used for knife sharpening.

The knives above have been sanded to their final shape. The next step is hardening the tips of the knives for durability. The stock steel bars or plates are too soft for a tool, but are hard enough to cut and form the knives. The knives are hardened by bringing the steel to a dull red glow in a forge, then immediately quenched in oil. The hot steel reacts with the oil to form a harder molecular structure within the knife.

But too hard is bad for a tool, especially a knife that is going to be thrown at hard wood - and will eventually bounce off the concrete floor. We need hardness, but tempered for shock absorption and to make sharpening easier. This is accomplished by placing the hardened knives in an oven at moderate heat (about 300 degrees) for several hours. This heating process relieves stress within the knife and tempers the steel. Sometimes the tempering process is repeated if the steel is still too hard and brittle and chips too easily upon impact.

As you can see, knife making is time consuming - and also quite noisy with all the cutting, grinding and sanding! But knife making can also justify creating something new from a broken tool. Below is a throwing axe that I broke. The head snapped off this stainless steel axe upon impact - so you can see how hard steel is not always good for throwing. Looking at the handle I envisioned a handle-heavy knife for no-spin throwing - so I made one. And it works!

Another modified stock knife is called the "bushcraft' knife. A bushcraft knife is heralded as an all-purpose knife. You can cut rope, cut kindling wood, slice lunch meat or field dress an elk. A bushcraft knife is suitable for any camping or hunting trip - or just for your glove box or truck tool box.

Bushcraft knives are all business, and not normally fancy (although there are "collector" bushcraft knives that cost hundreds of dollars and will never be used in the field.) One characteristic of bushcraft knives is that they are often created from butcher knives - often by necessity or due to frugality.

The best bushcraft knives have thicker blades and are "full tang", that is, the blade extends the full length of the handle. I took the knives shown above and cut the blades to a new shape.

Next, I created a new edge bevel on the blades, then finished sharpening the new bushcraft knives.

The next step will be to make sheaths for these new bushcraft knives. Then I will have heavy, versatile knives for my next hunting or camping trip. The smaller knife is also suitable for everyday carry, especially in a horizontal belt sheath. But sheath making is the topic for another article.

Comments